Since the Bronze Age, pliers have been essential for handling hot objects. The word “pliers” itself comes from the French “pincers,” meaning “to pinch,” reflecting their fundamental action.

The Industrial Revolution sparked a surge in tool innovation, leading to today’s diverse plier designs. Among these, slip-joint pliers – especially the tongue-and-groove style popularized by ChannelLock in 1933 – are favorites for both DIYers and pros. Their versatility shines in plumbing and general tasks, thanks to an adjustable pivot that grips various sizes.

Let’s explore the key features, real-world uses, and rich history of slip-joint pliers. Understanding these tools better will make your projects smoother and more efficient.

A Journey Through Time: The History of Pliers

Pliers have a long and fascinating history, starting with simple bronze tongs around 3000 BC. [24] These earliest versions, with their basic tong shape and central pivot, remained remarkably consistent even through Roman times. [25]

The Industrial Revolution, however, brought transformative changes. The need for specialized tools fueled rapid development. A landmark innovation was Klein Tools’ introduction of Lineman’s Pliers in 1857. [25] Demonstrating their robust build, a set of Klein pliers from 1904 was discovered still functional decades later. [25]

Driven by a commitment to innovation, Klein Tools expanded their range to over 100 plier types and sizes within their first half-century. [25] This dedication cemented their reputation as a leading force in American plier design.

The 1920s saw another key invention: VISE-GRIP pliers, created in 1924 by a Danish blacksmith seeking a “helping hand” in his workshop. [25] After numerous prototypes, he perfected the distinctive locking mechanism that became VISE-GRIP pliers’ signature. [25]

Perhaps the most significant advancement for slip-joint pliers came in 1933. ChannelLock (then known as Champion-DeArment Tool Company) introduced what is widely recognized as the first modern tongue and groove design. [26] Chief Engineer Howard Manning’s innovative multi-position, tongue-and-groove slip-joint pliers quickly became a success. [26] The name “Channellock” became so strongly associated with this plier type that the company officially rebranded itself as CHANNELLOCK in 1963 to protect its valuable trademark. [26]

CHANNELLOCK’s journey began in 1886, with blacksmith George B. DeArment in Evansburg, Pennsylvania, hand-forging farrier’s tools. [26] Facing early hardship, the company lost its cash reserves due to bank fraud in 1893, yet they persevered. [26] By 1904, they had relocated to a larger facility in Meadville and broadened their product offerings. [26]

CHANNELLOCK has secured multiple patents over the years, including a 1965 patent for a conical surface on the cam side of their tongue and groove pliers. [26] Today, from their two Meadville, PA, facilities totaling 260,000 square feet, they employ over 350 associates and produce more than 75 plier types and sizes. [26]

The ongoing story of pliers demonstrates how relentless innovation and a dedication to quality have shaped these vital tools. From basic ancient tongs to today’s sophisticated slip-joint designs, each step has enhanced plier versatility and effectiveness for professionals and homeowners alike.

Slip-Joint Pliers: Design and Functionality

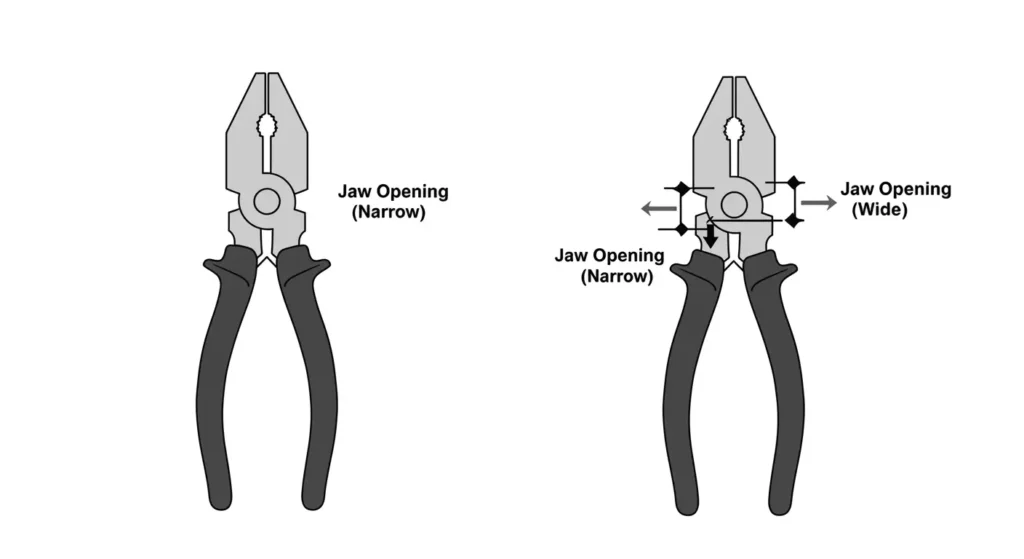

What sets slip-joint pliers apart? It’s their adjustable design, allowing the jaws to grip objects of different sizes. [27] These adaptable hand tools feature a pivot point, or fulcrum, that can be shifted, changing the jaw opening for diverse tasks. [28]

Understanding the Design

Look closely, and you’ll see serrated jaws with two tooth patterns. Fine teeth near the jaw tips provide precision for small items, while coarser teeth at the back offer a stronger bite for larger nuts and bolts. [4] The curved jaw shape is specifically designed to enhance grip and turning force on pipes, rods, and pins. [6]

How the “Slip Joint” Works

The adjustable pivot, or “slip joint,” is key. By fully opening the pliers, you engage a sliding mechanism. [28] This pivot point shifts position, letting you change the pliers’ jaw width.

Here’s a simplified view of the adjustment:

- Fully open the pliers past their usual range.

- Slide the pivot to your desired width.

- Return to normal use with the new, wider (or narrower) jaw setting.

Essential Components

Slip-joint pliers consist of several key parts: [8]

- Durable Jaws: Made to last and withstand wear, these are the working end of the pliers, directly contacting your materials.

- Versatile Gripping Surface: Featuring both smooth and serrated sections, jaws are designed for diverse gripping needs.

- Adjustable Joint: The pivot point connecting handles and jaws – the heart of the “slip joint” mechanism.

- Comfortable Handles: Typically coated with non-slip materials, handles ensure a secure and comfortable grip.

Modern pliers often add features like built-in wire cutters or specialized grip zones for added functionality. [6] Jaw capacity usually reaches about 1.5 inches, with standard lengths around 8 inches. [6]

When choosing pliers, construction quality matters. Look for even jaw surfaces, sharp teeth, and handles that move smoothly without any looseness at the pivot. [4]

From basic home fixes to professional plumbing jobs, slip-joint pliers are remarkably versatile. [29] Their adjustable size and features like cross-hatched jaws and wire cutters truly make them toolbox essentials. [6]

Exploring Today’s Slip-Joint Pliers: Types and Options

Today’s market presents a wide variety of slip-joint pliers, each tailored to different tasks. They’ve come a long way from simple designs, now boasting specialized features and advanced materials.

Standard Slip-Joint Pliers: The Reliable All-Rounders

Ranging from 4 to 9 inches, standard models are everyday workhorses. [9] Often constructed from durable nickel chromium steel, they’re designed for longevity. [10] Many feature comfort grips, like ProTouch™, to reduce hand fatigue. [10] Machined jaws enhance grip, and induction-hardened cutting edges stay sharper for longer. [10]

Multi-Groove Pliers: Enhanced Adjustability

Multi-groove designs offer more adjustment positions, increasing versatility. Their tongue and groove mechanism allows for precise sizing for both small and large objects. [11] Coarse teeth ensure a strong grip on various materials, from pipes to fasteners. [11] Dual-layer, textured “dipped” handles are common now, improving control and comfort. [11]

Specialty Slip-Joint Pliers: For Targeted Tasks

Professionals often need specialized tools. Manufacturers have developed slip-joint pliers for specific trades and tasks:

- Heavy-Duty Models: Built with extra-strong jaws and robust construction for tougher jobs. [12]

- Oil-Filter and PVC Pliers: Designed with unique grip patterns tailored for plumbers and mechanics working with oil filters and PVC pipes. [12]

- Talon Grip™ Series: High-end options featuring advanced gripping tech, often available in various colors and sizes, representing a premium segment. [13]

Prices vary with quality and features, starting from around $5 for basic models up to $10 or more for professional-grade pliers with enhanced features. [2] Premium models, offering features like user-serviceable pivots or cushioned handles, typically fall into the higher price range. [2]

Ongoing innovation in slip-joint pliers brings features like:

- Versatile 3-zone jaws that adapt to grip various shapes. [1]

- Integrated wire cutters for added utility. [1]

- Adjustable fasteners for customized tension. [1]

Modern pliers frequently meet or exceed ANSI standards, ensuring reliable performance and safety. [10] The market continues to evolve, with companies like Knipex contributing to ongoing advancements. A key design challenge remains: finding the ideal balance in pivot tension – easy adjustment yet firm positioning. [2]

Everyday Tasks and Specialized Jobs: Applications of Slip-Joint Pliers

From DIYers to seasoned professionals, slip-joint pliers are indispensable. These versatile tools are at home in any toolbox, ready to tackle a wide range of tasks.

Around the House: Home Repairs

Slip-joint pliers are essential for home maintenance. They excel at assembling and disassembling furniture, appliances, and countless household items. [14] Need to tighten a loose screw, bolt, or pipe? Slip-joint pliers are up to the task. [14] Their ability to grip from multiple angles makes them ideal in real for working in tight corners and confined spaces. [3] And the serrated teeth, often with a V-notch design, significantly improve their grip on nuts. [15]

Plumbing Powerhouse: Plumbing Applications

Plumbing is where slip-joint pliers truly shine. Their robust construction and adjustable jaws make them perfect for:

- Faucet installation and removal.

- Tightening and loosening pipe fittings.

- Fixing leaky plumbing fixtures.

- Managing spring-tension hose clamps commonly found in plumbing systems. [14]

With a jaw opening often reaching over 2 inches, they can handle various pipe diameters. [15] A zinc-plated finish, common on many plumbing-oriented pliers, provides crucial corrosion resistance in damp environments. [15]

Electrical Projects (With Caution): Electrical Work

Electricians find slip-joint pliers highly useful for many tasks. The built-in wire cutter is ideal for quickly trimming electrical wires. [14] Dual-material handles often enhance grip and control, reducing fatigue – important for detailed electrical work. [6] **However, it is critically important to remember that standard slip-joint pliers are NOT insulated.** Always ensure power is completely off before working on electrical circuits and use properly insulated tools for live electrical work.

Under the Hood: Automotive Uses

For automotive maintenance, slip-joint pliers are invaluable, aiding in:

- Fast removal and installation of spring-tension hose clamps in engine compartments. [3]

- Battery terminal maintenance.

- Working with nuts and bolts, especially in tight engine spaces.

- Gripping and maneuvering various car parts. [4]

Their drop-forged construction and heat-treated jaws provide the strength and durability needed for automotive tasks. [15] Adjustable pivot tension allows you to fine-tune control for different automotive components. [15]

Beyond these common uses, slip-joint pliers can temporarily clamp objects, twist wires or materials, and even assist in delicate tasks in fields like medical equipment maintenance, where managing wires and pins is crucial. [4] The variety of serrated teeth patterns ensures a secure grip on diverse materials, from slick plastic to rough metal. [6]

Choosing the Right Tool: Key Features of Slip-Joint Pliers

Selecting the best slip-joint pliers means understanding key features that impact their performance and lifespan. Consider these factors when choosing your next set.

Jaw Design: Grip Strength and Versatility

Jaw design is paramount. Many modern pliers feature angled teeth, effectively creating a Pipe wrench -like grip that resists slipping. [5] Serrated jaws combined with dedicated pipe grip zones ensure solid contact with various shapes. [16]

Look for pliers with multiple gripping zones, offering versatility for different tasks: [2]

- Cross-hatched areas for general gripping and pulling tasks.

- Specialized fastener grip zones specifically designed for securely turning nuts and bolts.

- Non-marring pipe grip zones – useful for plumbing and delicate materials. [6]

A good jaw design often incorporates fine teeth near the tips for delicate work, transitioning to coarser teeth towards the rear for heavier-duty gripping. [4]

Handle Materials: Comfort and Control

Handle design has come a long way. Modern slip-joint pliers often utilize dual-material handles for an optimal blend of comfort and control. [6] This typically combines:

- A wider, rounded handle shape to distribute hand force evenly, reducing pressure points.

- Thin, non-slip outer grips that add cushioning without making the handles bulky. [5]

High-end pliers often use thermoplastic rubber (TPR) for handles, providing superior grip and reduced hand fatigue during prolonged use. [17] Some brands feature signature grips like CHANNELLOCK BLUE® [16] or employ double-dipped grip technology for enhanced comfort and durability. [18]

For professionals working at height, some premium models even integrate tether points into their ergonomic handles, adding a safety feature. [6] The chosen handle material directly affects tool control and how comfortable the pliers are to use over extended periods. High-impact rubberized grip zones further improve handling. [6]

When assessing handle quality, ensure surfaces are even and handles pivot smoothly without any wobble, indicating good manufacturing and tight tolerances. [4] While comfort grips enhance usability, remember they are generally not designed to provide electrical insulation. [4]

Mastering the Technique: How to Use Slip-Joint Pliers Effectively

To get the most out of your slip-joint pliers and ensure safety, proper usage technique is key. These versatile tools perform best when handled with specific methods.

Joint Adjustment: Setting the Right Width

Begin each task by selecting the correct jaw opening. The slip-joint mechanism allows for a wider jaw range via the adjustable pivot. [19] For maximum grip strength, aim to keep the jaws as parallel as possible to the workpiece. [20] To adjust, fully open the pliers and slide the pivot to the desired position for the object you are gripping.

Grip Technique: Achieving Firm Control

Proper hand and tool positioning are crucial for firm control. When gripping, ensure the top jaw aligns closely with the lower jaw as you close the handles. [21] This helps prevent the jaws from slipping. For optimal grip, fully seat the pliers onto the object, aiming for secure, three-point contact. [21]

Key techniques for effective use:

- Adjust jaw width for a comfortable yet snug grip on the material. [20]

- Strive for parallel jaw alignment to maximize gripping force. [20]

- When applying force, pull the pliers towards yourself rather than pushing away for better control. [20]

- Regularly lubricate the hinge pin with a drop of light machine oil to maintain smooth operation. [22]

Prioritizing Safety: Essential Considerations

Safety must always come first. Practice safe tool handling and maintenance:

Pre-Use Inspection: Before each use, carefully inspect your pliers for:

- Any broken or chipped parts that could compromise tool integrity. [23]

- Signs of the rust or corrosion that could weaken the metal. [23]

- Cracks in the handles or jaws. [23]

- Excessive wear on the gripping jaws. [23]

- Looseness or excessive play in the pivot joint. [23]

Safe Operating Practices:

- Always wear appropriate eye protection, especially when using pliers with a wire-cutting feature. [23]

- Never, under any circumstances, use slip-joint pliers on live electrical circuits. [23] Remember, comfort grips offer no protection from electrical shock. [23]

- Avoid extending plier handles with pipes or other objects to increase leverage. This is unsafe and can break the tool or cause injury. [23]

- Keep wire-cutting edges sharp and clean. Sharp cutters require less force and offer better control. [20]

Regularly oiling the pivot bolt and hinge pins is essential for preventing rust and maintaining smooth, reliable operation. [22] Good maintenance coupled with careful technique will ensure your slip-joint pliers remain dependable tools for years to come.

In Conclusion: The Enduring Value of Slip-Joint Pliers

From their ancient beginnings to today’s refined designs, slip-joint pliers have undergone a remarkable evolution. Equipped with adjustable mechanisms, specialized jaws, and comfortable handles, they are indispensable tools for professionals across trades and for countless DIY projects.

By understanding their capabilities – from the nuances of jaw designs to proper usage methods – users can truly maximize the effectiveness of slip-joint pliers. The blend of robust construction, ergonomic design, and precise adjustability delivers consistent, reliable performance, task after task.

Remember, to ensure both optimal performance and safety, regular inspection and maintenance are crucial. Routine checks, appropriate protective gear, and careful technique not only extend the lifespan of your pliers but also minimize the risk of injury. When well-maintained and used correctly, slip-joint pliers prove their enduring value as essential components of any well-equipped toolbox.

References

- Tekton.com – Pliers Set PLR99020

- Toolguyd.com – Slip Joint Pliers Question

- Idealind.com – 8-slip joint pliers

- HowStuffWorks.com – Repairs That Require Slip-Joint Pliers

- Tekton.com – Angle Nose Slip Joint Pliers Set PGA16103

- CrescentTool.com – HTZ28CG-8-Z2 Dual-Material Slip Joint Pliers

- Knipex.com – Pliers Knowledge: Joint Composition

- Knipex Blog – Anatomy of Pliers

- ChannelLock.com – Slip Joint Pliers

- IrwinTools.com – Slip-Joint Pliers

- Steelmantools.com – 10-inch Groove Joint Pliers 95209

- HomeDepot.com – Slip Joint Pliers at Home Depot

- SnapOn.com – Slip Joint Pliers

- AbascoTools.com – Benefits of Using Slip Joint Pliers For Your Home Projects

- CHHanson.com – 11″ Soft Grip Water Pump Slip Joint Pliers

- ChannelLock Shop – Model 528 Slip Joint Pliers

- WithCharacter.com – The Slip Joint Pliers

- StanleyTools.com – 6-slip joint plier (STHT84401)

- Diversitech-Global.com – Hand Pliers: Types, Parts, and Application

- CCOHS.ca – Hand Tool Safety – Use of Pliers

- ThisOldHouse.com – How to Choose and Use Pliers

- IADC.org – Safety Meeting Topics: Hand Tool Safety – Use of Pliers

- UCANR.edu – Hand Tool Safety Tips (PDF)

- TheInventors.org – History of Pliers

- HausOfTools.com – A History of Pliers

- ChannelLock.com – Company History

- RS-Online.com – Pliers Guide

- Wikipedia – Slip Joint Pliers

- Daitool.com – 10 Different Types of Pliers and Their Uses

- Bosch 1191VSRK Hammer Drill Review - March 12, 2025

- JOREST Connectable Contour Gauge Review - March 11, 2025

- Klein 11061 Wire Stripper: Tested on 1,000+ Wires - March 8, 2025