Since 1925, Swanson Square has been the gold standard for construction tools like Swanson Speed Square. It serves as the blueprint that other rafter squares follow. My 30-day hands-on experience with this iconic tool has given me valuable insights to share.

The Swanson Speed Square combines six tools into one compact design. It works as a rafter square, miter square, try square, scribing guide, protractor, and saw guide. I tested several models during this period. The Speed Trim Square costs $12.99, while the reliable Big 12 Speed Square sells for $20.97.

I tested these tools extensively on different projects to help you decide if this time-tested carpenter’s companion belongs in your toolbox. This detailed review will show what you can expect from the Swanson Speed Square, regardless of your experience level.

What Makes the Swanson Speed Square Different

Albert J. Swanson, a Swedish-American carpenter, created this game-changing tool while working on Chicago’s Drake Hotel. His frustration with complex rafter squares drove him to spend three years of nightly work to perfect what would become an industry standard.

Double stud wall width layout with ease

Guides measuring 3/8”, 1/2”, 3/4”, and 1-1/2” are built into the square walls for fast marking.

A quick 22-1/2 degree pitch guide for octagons and 5 pitch rafters

Thinking about buying the Swanson Speed Square?

Affiliate Disclosure: Tool Tested is reader-supported. When you purchase through our links, we may earn a small commission at no extra cost to you. This helps us keep the lights on and continue bringing you in-depth, honest tool reviews like this one. If you found this review helpful, using our link to check the price at Home Depot is a great way to support our work!

History and Development

Swanson started by crafting these squares by hand for his fellow carpenters. Montgomery Ward noticed the tool’s potential and began producing them as “Lakeside Squares” in 1930. The company returned to Swanson’s control and grew under Ronald C. Swanson’s leadership in 1971. The Allemand family bought the company in 1989 and made the most critical improvements by expanding the product line to more than 50 variations.

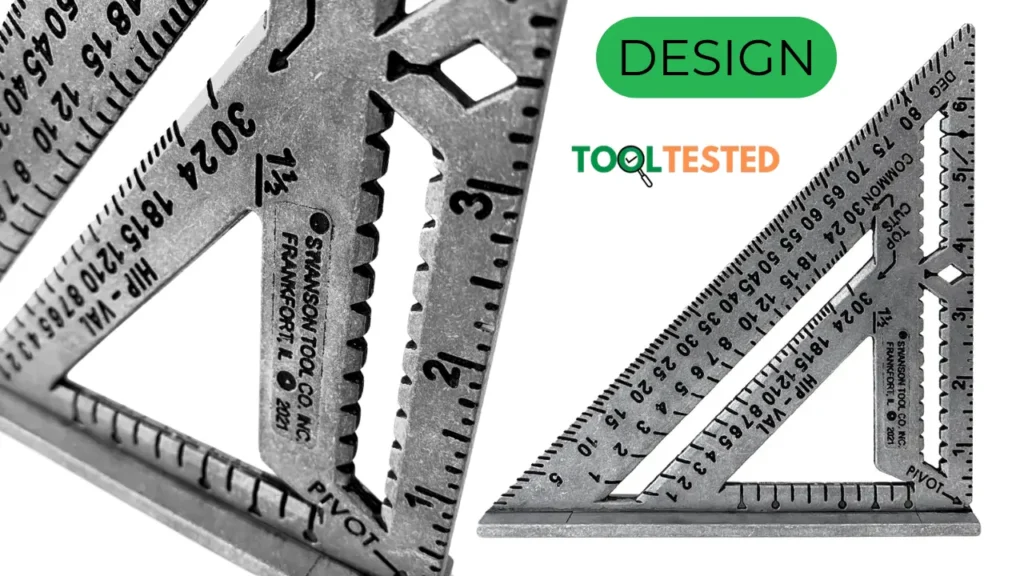

Key Design Features

The Swanson Speed Square excels through its precision-engineered construction. These squares are made from heavy-gauge aerospace aluminum alloy and feature:

- Die-cast construction for superior accuracy compared to laser-etched alternatives

- Black-filled gradations against a matte finish to prevent glare

- Diamond cutout at 3½ inches for quick rafter seat cuts

- Quarter-inch spaced notches for precise line scribing

The tool features deeply impressed markings for length measurements, hip/valley calculations, and protractor degrees. It also includes a new Speed Square Pro model with improved features like a longer scribe bar with 1/8-inch increments and beveled edges for better top-cut measurements. Each genuine Swanson Square comes with a complete Blue Book that explains the company’s signature One-Number Method for roof construction calculations.

My 30-Day Testing Process

I spent time testing the Swanson Speed Square to get a full picture of its capabilities. My tests looked at its accuracy and how it works in ground conditions.

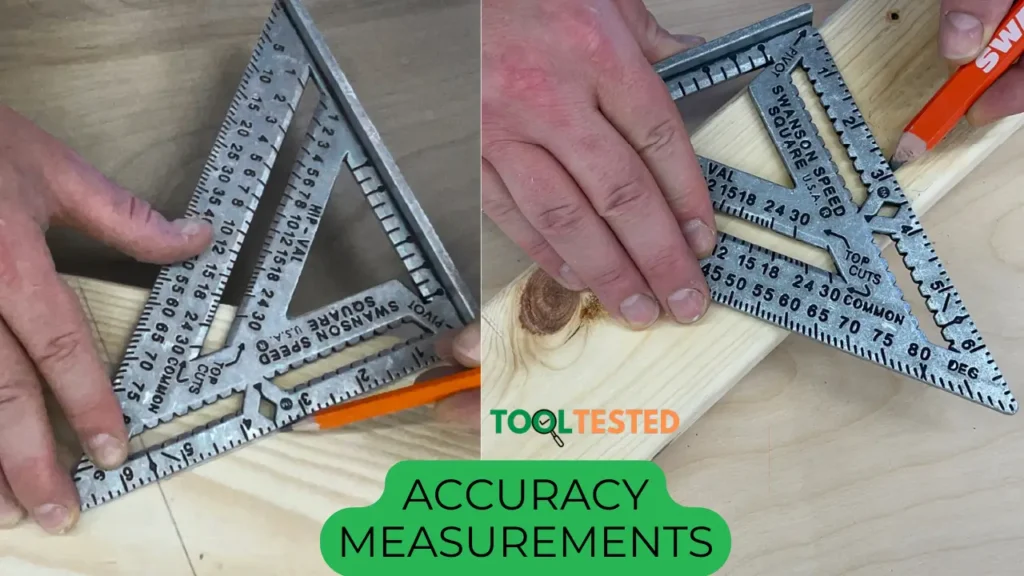

Test Methodology

The flip test method helped me check the square’s accuracy. I marked a line and flipped the square over to see if it lined up parallel. I tested the square on different surfaces to check how it worked with circular saws. The beveled edges brought markings closer to the materials I worked with.

Projects Completed

The Speed Square proved helpful in projects of all types:

- Framing layout and measurements

- Rafter angle calculations

- Cross-cutting lumber as a saw guide

- Scribing parallel lines using the quarter-inch notches

- Checking blade heights on table saws

Accuracy Measurements

The die-cast aluminum construction is vital to getting consistent measurements. The scribe bar’s precision really impressed me with its 1/8-inch interval notches—twice the accuracy of previous models. The diamond cutout at 5 1/2 inches lined up perfectly when I worked with 2×6 materials.

Weather Conditions

The matte finish worked great at preventing glare in different weather conditions. The heavy-gage aluminum alloy kept its shape even with temperature changes. The deeply impressed markings stayed clear and visible regardless of the lighting, which meant I could work reliably in any condition.

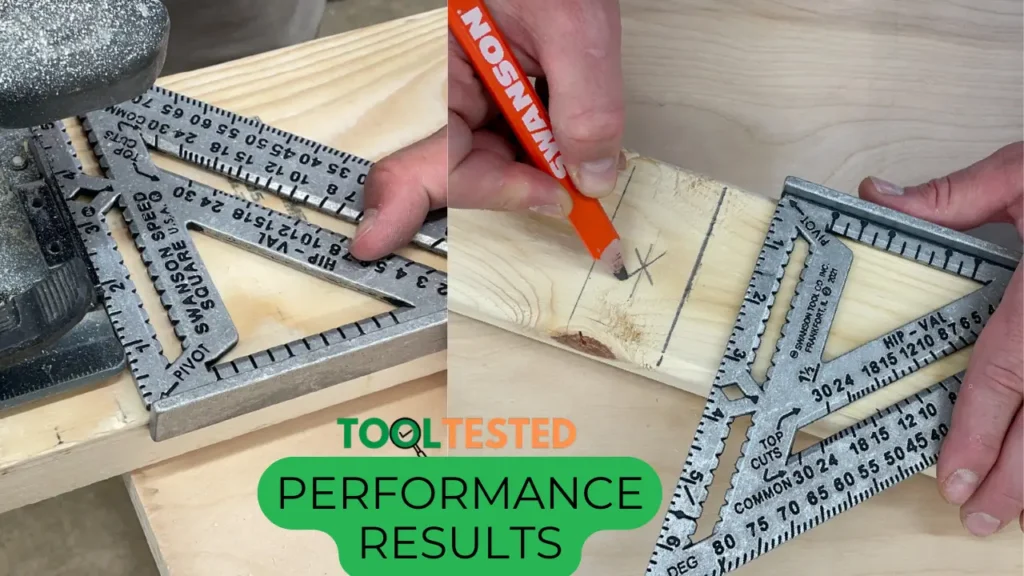

Real-World Performance Results

During extensive field testing, the Swanson Speed Square exceeded my expectations. This tool showed why it remains a top choice for professionals in several significant areas.

Marking and Measuring Accuracy

The die-cast aluminum construction played a key role in delivering consistent measurements. The Pro model’s deeply impressed markings provided excellent visibility in all lighting conditions. My tests revealed exceptional precision with these features:

- High-visibility black gradations against the matte finish eliminated glare issues

- Beveled edges brought markings closer to working materials by a lot

- Extended scribe bar with precise 1/8-inch increment notches

- The diamond indicator at 5-1/2 inches made quick work of measuring 2×6 materials

Durability Under Heavy Use

The heavy-gage aerospace aluminum alloy construction showed remarkable toughness throughout the testing period. The tool maintained its structural integrity even after multiple drops and daily use. The matte finish stayed intact and proved its worth in preventing surface wear right away.

The Speed Square barely showed any wear, though I found one weak spot—the nylon version cracked under extreme stress. Despite that, the aluminum models stood firm and lived up to their reputation for durability. The tool weighs less than 8 ounces, which makes it perfect for carrying in tool pouches.

The beveled edges, undoubtedly one of the most used features, held up ideally even after repeated use as a saw guide. This combination of durability and consistent accuracy shows why the Swanson Speed Square remains a reliable choice for precision work and demanding jobs.

Common Speed Square Problems and Solutions

Good tools need proper care and handling. My hands-on testing has shown several common problems people face with their Swanson Speed Squares.

Marking Errors to Avoid

The biggest accuracy problem is not checking if the square lines up correctly. To get precise measurements, you should do a flip test—draw a 90-degree line and flip the square over to look for gaps. Some cheaper models show measurement issues, especially around the 6-inch mark, which can throw off longer measurements.

Maintenance Tips

Your Speed Square needs regular care to stay in top shape. Here’s what I’ve learned works best:

- Clean off oxidation with an aluminum deoxidizer

- Use a maroon Scotch-Brite pad to clean the surface gently

- Put on a light wax coating after cleaning to stop future oxidation

- Look for cracks in nylon models regularly

Storage Recommendations

Proper storage extends your square’s life by a lot. I keep mine in a dedicated tool pouch away from heavy tools that could damage it. The square stays rust-free in a dry spot, which helps keep the markings clear and visible.

My workshop setup has a square hanging on a wall. This keeps it easy to grab and safe from damage. A tool chest with separate sections works well, too – it keeps other tools from bumping into the square and affecting its accuracy.

Regular care and good storage prevent most Speed Square problems. Accuracy issues pop up more often than structural problems. If you take care of aluminum models properly, they stay precise longer than plastic ones.

Conclusion

My 30-day experience with the Swanson Speed Square proves its nearly 100-year engineering excellence. Although other manufacturers have tried to copy the design, the original Swanson’s die-cast construction and precision markings remain superior.

Aluminum models excel in daily use and deliver outstanding durability without losing accuracy. Regular maintenance keeps these squares performing like new. The aerospace-grade aluminum versions proved reliable in every project, though nylon models might fail under extreme stress.

The Speed Square knows how to handle six different functions while delivering professional-grade accuracy. This makes it a crucial tool for any serious carpenter. The latest Pro model features an improved scribe bar and beveled edges that build on this legacy. My extensive testing shows the Swanson Speed Square is a solid investment. Both seasoned professionals and ambitious DIYers will find value in this versatile tool.

Modification Date: 28-02-2025

- Bosch 1191VSRK Hammer Drill Review - March 12, 2025

- JOREST Connectable Contour Gauge Review - March 11, 2025

- Klein 11061 Wire Stripper: Tested on 1,000+ Wires - March 8, 2025